Agriculture has evolved tremendously over the past few decades, shifting from traditional manual practices to highly mechanized operations powered by modern equipment. Among the many innovations that have reshaped farming efficiency, 36'' rubber tracks have become a game-changing upgrade for agricultural machinery. From tractors and harvesters to sprayers and combines, rubber track systems have significantly improved traction, reduced soil compaction, and enhanced productivity on diverse terrains.

This article explores how 36'' rubber tracks contribute to agricultural efficiency, their working principles, advantages, and how farmers can maximize their use for better long-term performance.

1. Understanding 36'' Rubber Tracks

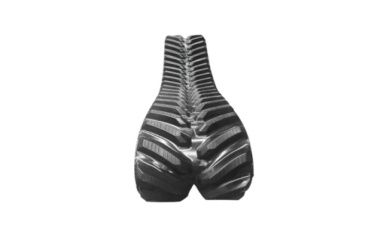

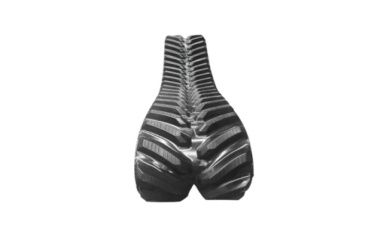

A 36-inch rubber track refers to a continuous rubber belt that measures 36 inches in width. It replaces traditional steel tracks or tires on agricultural machines, serving as the interface between the vehicle and the ground. Unlike steel tracks, rubber tracks are composed of advanced materials like natural rubber compounds, synthetic additives, and embedded steel cords that ensure flexibility, strength, and resilience under heavy loads.

Rubber tracks distribute the weight of heavy machinery over a larger surface area, minimizing ground pressure. This not only protects the soil from excessive compaction but also allows tractors and harvesters to operate in wet, soft, or uneven conditions without getting stuck.

Key Components of a 36'' Rubber Track System:

Rubber Layer: Provides flexibility, grip, and wear resistance.

Steel Cords: Reinforce the track’s internal structure for strength and stability.

Drive Lugs: Engage with sprockets to transfer power efficiently.

Tread Pattern: Designed to maximize traction and self-cleaning performance.

2. Why Rubber Tracks Are Replacing Tires in Agriculture

Farmers across the world are increasingly adopting rubber track systems instead of traditional tires for high-powered agricultural equipment. The primary reasons include better traction, less soil disturbance, and superior adaptability across terrain types.

Enhanced Traction and Stability

Unlike tires that rely on a relatively small contact patch, 36'' rubber tracks provide a larger surface area in contact with the ground. This expanded footprint delivers superior traction on slippery, uneven, or muddy terrain. The tracks maintain consistent ground contact even on slopes or soft soil, reducing slippage and power loss. As a result, farmers experience improved pulling capacity, smoother operation, and greater control over their machinery—critical when towing heavy planters, tillers, or grain carts through challenging field conditions.

Reduced Soil Compaction

One of the biggest issues with heavy farm machinery is soil compaction, which reduces root growth and lowers yield potential. The broad footprint of 36'' rubber tracks spreads the machine’s weight more evenly, minimizing pressure on the soil and preserving its aeration and fertility.

All-Weather Performance

Agriculture doesn’t pause for the weather, and this is where rubber tracks show their versatility. Whether it’s a wet spring or a dry summer, rubber tracks maintain reliable traction and maneuverability. Their tread patterns are designed for self-cleaning—mud and debris are efficiently expelled during operation, preventing buildup that would otherwise compromise grip.

Better Maneuverability

Because rubber tracks allow even pressure distribution, they reduce ground damage during turns and eliminate rut formation. This is particularly important for precision farming and operations in delicate or repetitive fieldwork zones.

3. Applications of 36'' Rubber Tracks in Agriculture

The versatility of 36'' rubber tracks allows them to be installed on a wide range of agricultural machines. Their robust design supports both small-scale farms and large commercial operations.

Equipment Type | Application of 36'' Rubber Tracks | Advantages |

Tractors | Plowing, tilling, hauling | Improved traction, reduced slippage |

Harvesters & Combines | Crop harvesting | Minimizes field damage, better stability |

Sprayers | Fertilizer and pesticide application | Consistent movement on soft soil |

Seeders & Planters | Precision planting | Smooth, consistent planting depth |

Spreaders | Distribution of lime or compost | Less rutting and better maneuvering |

Grain Carts | Transport of harvested crops | Handles heavy loads without sinking |

In mountainous or lowland areas, where soil consistency changes drastically, 36'' rubber tracks maintain stability and traction, ensuring consistent field operations throughout the season.

4. Advantages of Using 36'' Rubber Tracks in Farming Operations

Increased Productivity

By providing excellent traction and stability, rubber tracks enable machinery to operate faster and more efficiently. Farmers spend less time dealing with stuck machines or soil damage, allowing more acreage to be covered per day.

Reduced Fuel Consumption

Improved traction means less wheel slippage and better power transfer, leading to reduced energy loss. In field tests, tracked tractors have shown up to 15% better fuel efficiency than wheeled counterparts when working on soft or uneven terrain.

Lower Maintenance Costs

Although rubber tracks have a higher initial cost, they tend to last longer than tires when used properly. Their reinforced structure resists punctures and blowouts, which are common problems with pneumatic tires. Additionally, smoother operation reduces mechanical strain on the vehicle’s drivetrain and suspension.

Better Field Accessibility

With their ability to handle muddy, sandy, or uneven surfaces, machines equipped with 36'' rubber tracks can access fields earlier in the season and stay operational longer after rainfall. This extended working window can make a significant difference during planting and harvesting periods.

Operator Comfort

Rubber tracks provide smoother rides than steel tracks due to their ability to absorb vibration and shocks. Operators experience less fatigue, and sensitive equipment components benefit from reduced vibration exposure, improving longevity.

5. Design Innovations in 36'' Rubber Tracks

Modern manufacturers continuously refine rubber track designs to meet the evolving needs of agriculture. Key advancements include:

Multi-Layer Rubber Composites: Enhance flexibility while resisting wear and cracking.

Optimized Tread Patterns: Improve traction, reduce slippage, and enhance self-cleaning ability.

Heat-Resistant Rubber Compounds: Extend lifespan even in hot, abrasive environments.

Integrated Metal Inserts: Strengthen connections between rubber and steel cords for stability.

Noise Reduction Technology: Provides quieter operation during transportation and field use.

These innovations ensure that 36'' rubber tracks remain reliable and durable, even in demanding agricultural conditions.

6. Maintenance Tips for 36'' Rubber Tracks

Proper care and maintenance extend the lifespan and performance of rubber tracks. Here are practical steps every operator should follow:

Regular Inspection

Check for cuts, cracks, or missing tread sections.

Inspect tension levels—too tight causes excessive wear, while too loose increases slippage.

Examine sprockets and rollers for misalignment or wear.

Cleaning After Use

Mud, debris, and stones can accumulate between the lugs and undercarriage. Cleaning the tracks after each use prevents premature wear and ensures better traction.

Proper Storage

When not in use, park machinery on a dry, flat surface and avoid prolonged exposure to sunlight or oil spills. UV radiation and chemicals can degrade rubber compounds over time.

Scheduled Replacement

Although rubber tracks are durable, they eventually wear down. Regular inspection and timely replacement prevent downtime during critical farming operations.

7. Comparing 36'' Rubber Tracks to Narrower Track Options

While 18'' or 24'' tracks may be suitable for smaller or lighter equipment, the 36'' model provides superior ground pressure distribution and traction for large-scale operations.

Feature | 24'' Rubber Track | 36'' Rubber Track |

Surface Contact Area | Moderate | Large |

Soil Compaction | Medium | Low |

Traction Strength | Good | Excellent |

Fuel Efficiency | Moderate | Higher (less slippage) |

Ideal Use | Light tractors | Large tractors, harvesters |

For heavy-duty farming, particularly in soft or high-moisture environments, 36'' tracks provide unmatched performance and reliability.

8. Environmental and Economic Impact

Rubber tracks play an important role in sustainable farming practices. Reduced soil compaction improves crop root systems, resulting in healthier soil ecosystems and higher yields. Furthermore, lower fuel consumption and extended machinery life contribute to reduced operating costs and a smaller environmental footprint.

The use of rubber tracks also reduces field rutting, which minimizes erosion and the need for expensive land leveling after harvest seasons. Over time, these benefits contribute to both ecological sustainability and financial efficiency.

9. The Future of Rubber Tracks in Agriculture

The demand for efficient, low-maintenance, and environmentally friendly agricultural solutions is driving continuous innovation in rubber track technology. Future developments are likely to focus on:

Smart Tracks: Integrated sensors for real-time wear and pressure monitoring.

Recyclable Materials: Eco-friendly production processes.

Hybrid Compositions: Combining rubber flexibility with carbon-fiber reinforcement for lighter yet stronger designs.

As farms become increasingly automated and connected, rubber tracks will continue to play a vital role in enabling precision agriculture and robotic farming systems.

10. Conclusion

The 36'' rubber track is more than just a mobility component—it’s a critical factor in modern agricultural efficiency. By offering superior traction, reduced soil compaction, longer operating hours, and lower maintenance needs, these tracks empower farmers to work smarter and more sustainably. Whether it’s planting, harvesting, or hauling, machines equipped with 36'' rubber tracks deliver consistent performance across various field conditions.

For farmers and agricultural equipment operators seeking durable, efficient, and well-engineered rubber tracks, it’s worth exploring reliable solutions from Shandong Bolin Machinery Co., Ltd. The company provides high-quality rubber track systems designed for long-term agricultural use. To learn more about their products or discuss the best track options for your farming needs, visit their official website or get in touch with their professional team today.